|

shaoxing libo group company

|

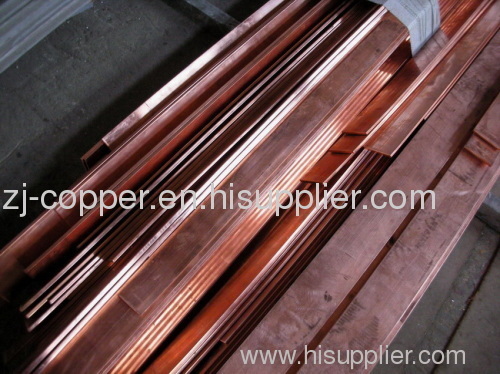

shaped copper bus bar

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

It has a high copper content (no less than 99.96%) and low oxygen content (no greater than 10 ppm).

1.Model

Trapezoidal bus bar (soft), Trapezoidal bus bar TTY( hardness)

Shaped bus bar(soft), shaped bus bar YTY(hardness)

Executive standard: Q/SDL0501-2006

2.1 Chemical Composition and Oxygen Content

Table 1

Chemical composition and oxygen content of copper rod

(Chemical Composition %, the content of microelement is less than or equal to)

Cu+Ag |

P | Bi | Sb | As | Fe | Ni | Pb | Sn | S | Zn | O | |

≥99.97 | 0.001 | 0.001 | 0.002 | 0.002 | 0.005 | 0.002 | 0.003 | 0.002 | 0.002 | 0.002 | 0.001 |

2.2 Electrical Performance

Table 2

Resistivity of Copper Bus Bar

2.1 Chemical Composition and Oxygen Content

Table 1

Chemical composition and oxygen content of copper rod

(Chemical Composition %, the content of microelement is less than or equal to)

Cu+Ag |

P | Bi | Sb | As | Fe | Ni | Pb | Sn | S | Zn | O | |

≥99.97 | 0.001 | 0.001 | 0.002 | 0.002 | 0.005 | 0.002 | 0.003 | 0.002 | 0.002 | 0.002 | 0.001 |

2.2 Electrical Performance

Table 2

Resistivity of Copper Bus Bar

2.1 Chemical Composition and Oxygen Content

Table 1

Chemical composition and oxygen content of copper rod

(Chemical Composition %, the content of microelement is less than or equal to)

Cu+Ag |

P | Bi | Sb | As | Fe | Ni | Pb | Sn | S | Zn | O | |

≥99.97 | 0.001 | 0.001 | 0.002 | 0.002 | 0.005 | 0.002 | 0.003 | 0.002 | 0.002 | 0.002 | 0.001 |

2.2 Electrical Performance

Table 2

Resistivity of Copper Bus Bar

Model

DC Resistivity (Ω·mm2/m) | Conductivity(%IACS) | |

TTR\YTR | ≤0.017241 | ≥100 |

TTY\YTY | ≤0.01777 | ≥97 |

2.3 Mechanical Performance

The surface hardness of Trapezoidal bus bar shall be HB80—105, less than 206MPa, and elongation shall not below 35%.

2.4 Size Scope: T ≤ 24,H ≤ 150,H / t ≤ 50

2.5 Size Tolerance

Table 1

Size Tolerance Unit: mm

Height | Height Tolerance | Sole Edge | Sole Edge Tolerance |

H≤10.0 | -0.10 | T≤3.00 | -0.04 |

10.0< H≤18.0 | -0.20 | 3.00< H≤6.00 | -0.05 |

18.0 | -0.30 | 6.00< H≤10.00 | -0.06 |

30.0 | -0.60 | 10.00< H≤18.00 | -0.07 |

50.0 | -0.80 | 18.00< H≤24.00 | -0.08 |

80.0 | -1.00 |

2.6 Include angel of trapezoidal bus bar shall be produced according to the sample. The spacing between the two sides shall be same with the sample and below or equal to the size of feeler gauge in the form.

Height (mm) | Feeler Gauge (mm) |

H≤30.00 | 0.03×3 |

30.00 | 0.05×7 |

80.00 | 0.08×10 |

100.00 |

0.10×10 |

2.7 Shape Tolerance

When the length of trapezoidal bus bar is less than 500m, its facies medialis tortuosity shall not exceed 2.5mm; while, when the length is less than 1m, its straightness shall be as follows:

a,when a>2"and H>50mm,straightness≤ 2mm

b,when a≤2"and H≥50mm,straightness≤3mm

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

.gif)